-

Mobile Version

Scan with Mobile

- Member Center

1. Introduction and features

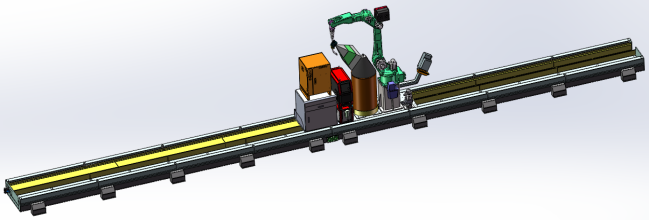

Ground-rail type robot welding station is one of the intelligentwelding products that developed by FSM. The main feature is its high cost-effectiveness, a reasonable size of ground-rail is used as the external motion additional axis for themovement of the robot, work with electrical cabinet/ MIG welder/ barrel welding wire and other necessary parts to achieve single robot but twin workstation operations.

The maximum work-piece size that designed for this intelligent welding workstation is 11000*1200*500mm, and thecommon work-pieces such as crane beam, h beam,platform beam, box beam, girder baffle, and also able to welding other small parts.

● Teaching-free programming (bid farewell to theoperation of traditional industrial robot teaching programming)

● Multiple welding mode (simple work-piecesupport photo to input, complex work-piece need input drawings)

● Support multiple welding modes (can adapt to various work-piece welding)

● Arc sensor (effectively solve the problem of weld quality caused by deformation during work-piece welding)

● Diversified welding processes

● Simple software design (convenient for students with different academic levels to quickly get started)

2. Technical parameters

No. | Item | Specification |

1 | Equipment area | 12300*800mm |

2 | Effective welding size | 11000*1200*500mm |

3 | Vision sensor | 3D vision (seam tracker) 3D linescanning (work-piece positioning) |

4 | Welding mode | BIM model driven welding (STEP, IFC format) |

5 | Suitable work-piece | Gantry type steel rack, hbeam ribplate, crane beam, H beam, platform beam, roof beam, box beam main seam |

6 | Sheetthickness | 6-18mm |

7 | Welding range | Flat welding, vertical welding (automatic corner wrapping) |

8 | Welding way | ● 80%Ar+20%CO2 ● 1.2mmsolid welding wire |

9 | Scanning time | Rough scanning time is 10-15 seconds Fine scanning time is 1.5 seconds per node |

友情链接:

济南鑫三达塑管熔接设备有限公司